![]()

THE SOLUTION

Enterprise Asset Maintenance Solution utilising a digital twin of a vast conveyor network for an industrial steel plant.

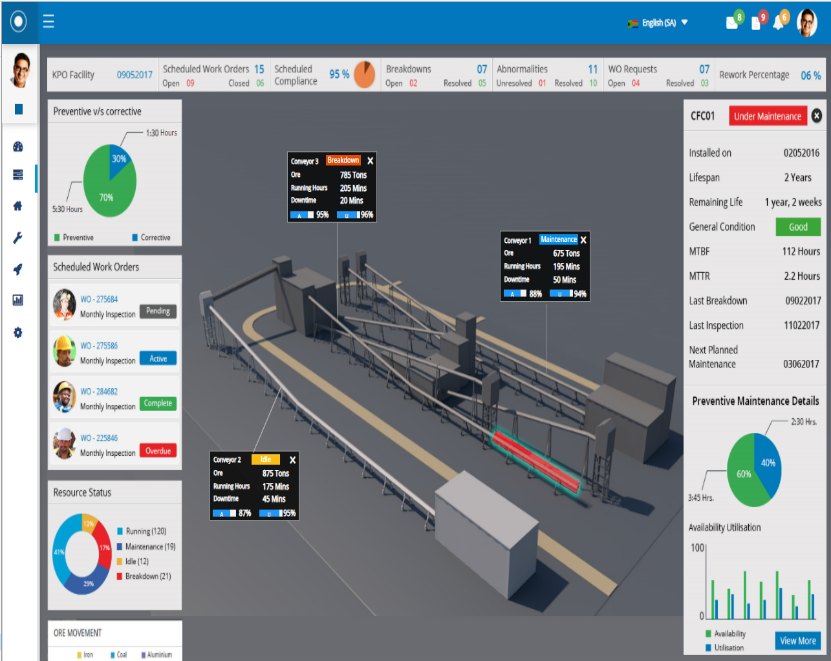

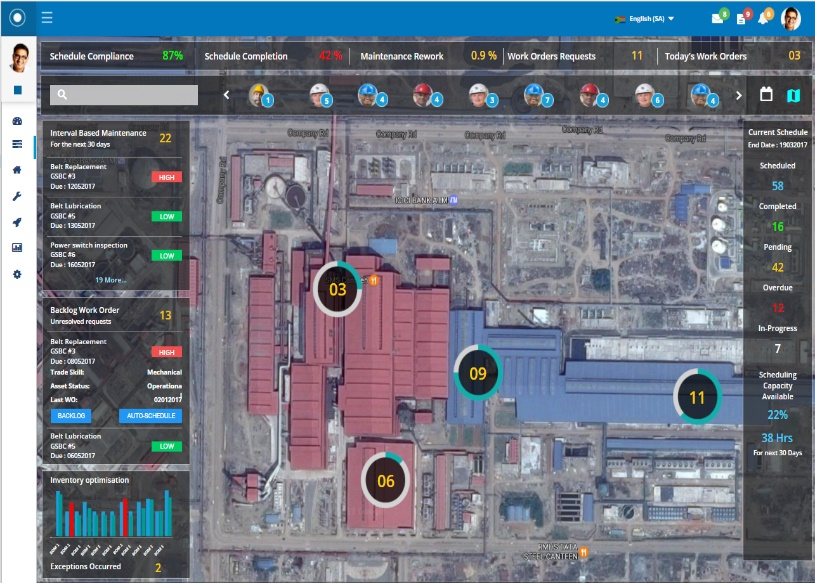

The complete digital transformation of an existing manual and disparate maintenance management for a top tier steel manufacturing facility. The solution entails intelligent maintenance scheduler, performance management reports, a 3D digital twin dashboard of the facility with 93 KM of conveyors visualised with their maintenance data, in real-time.

The maintenance and inspection process was transformed via a dedicated mobile application for artisans, mechanics and technicians. Maintenance personnel benefitted from real-time alerts and warnings related to the condition of the facility and the fulfillment of maintenance activities.

CLIENT

Tata steel Ltd, a multi-national steel producing conglomerate, among the top global steel companies with an annual crude steel capacity of 27 million tonnes per annum (MTPA). It is the world's second-most geographically diversified steel producer, with operations in 26 countries and a commercial presence in over 50 countries. Most of the material, where the solution was deployed is transported over almost 300 conveyors with a cumulative span of over 93 kilometer stretch within the confines of the facility.

THE PROBLEM STATEMENT

MANUAL ALLOCATION AND MONITORING

Scheduling, allocation, and fulfilment of maintenance inspection activities were done manually using a paper-based system and with various contractors with the relaying of information often taking place telephonically. The resultant administrative burden relating to hundreds of inspections performed over a regular interval for over 5000 components resulted in a host of inefficiencies and errors and prevented management from following a proactive approach with regard to their maintenance strategies.

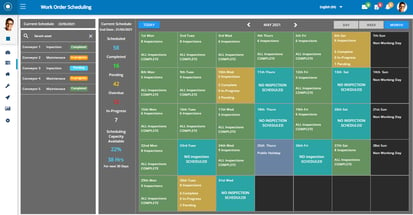

DEVUM’s process modeller and workflow engine was used to produce an automated maintenance scheduler with real-time alerts and reminders sent to key personnel.

INEFFICIENT CAPTURING OF INSPECTION DATA

The outcome and findings of inspections and work orders completed by field technicians were manually captured using paper-based checklists. Photographs for the same had to be manually tied to these handwritten reports. This process resulted in gross errors and inefficiencies reducing the effectiveness of maintenance and often resulting in unnecessary rework.

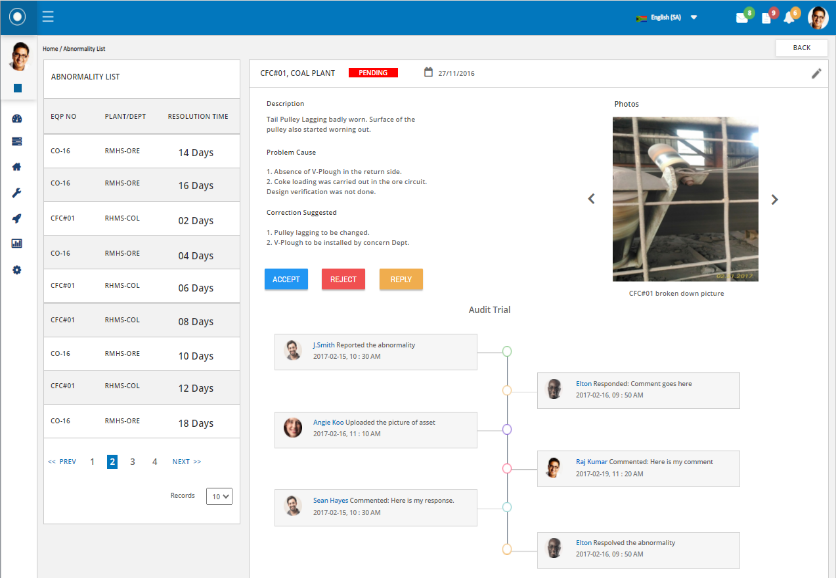

PAGE BUILDER was used to build a customized data acquisition mobile application, which was used by artisans to perform inspections, capture photographs, and report abnormalities to management in real-time.

CONVEYOR HEALTH MONITORING AND DATA

Conveyor condition and remaining lifespan were estimated based on the manual inspection findings inaccurate data often resulted in a false representation resulting in costly unplanned breakdowns. Management lacked an accurate and up-to-date overview of the condition of the conveyor network.

3D COMPOSER and page builder allowed for a digital twin of the conveyor network to be incorporated into an isometric dashboard. This dashboard was powered by metrics, data and KPI’s using DEVUM’s KPI Builder to provide management with accurate, reliable data.

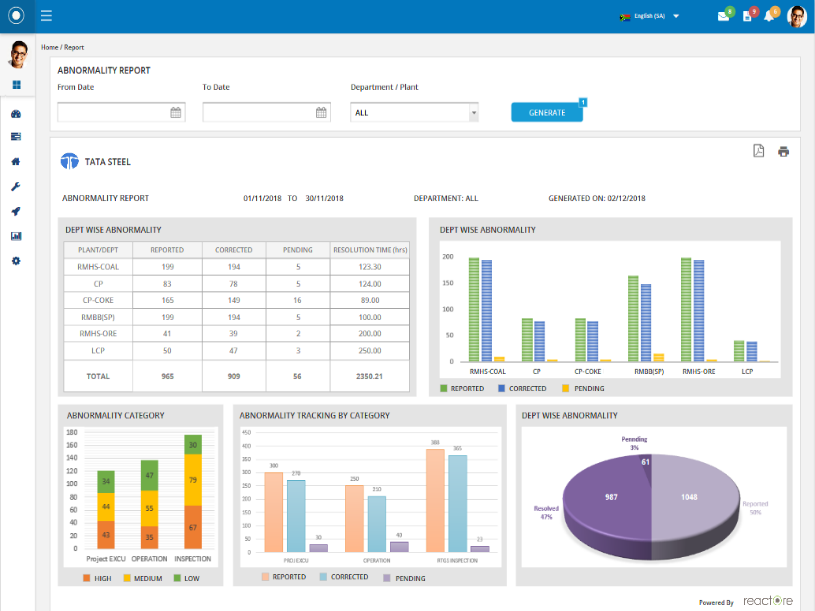

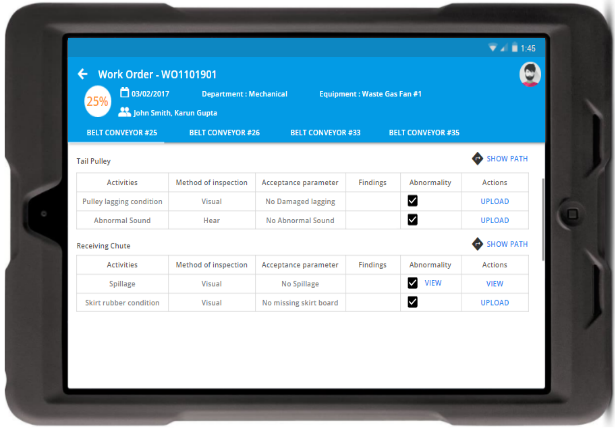

INFOGRAPHICS

SCREENSHOTS

SCREENSHOTS

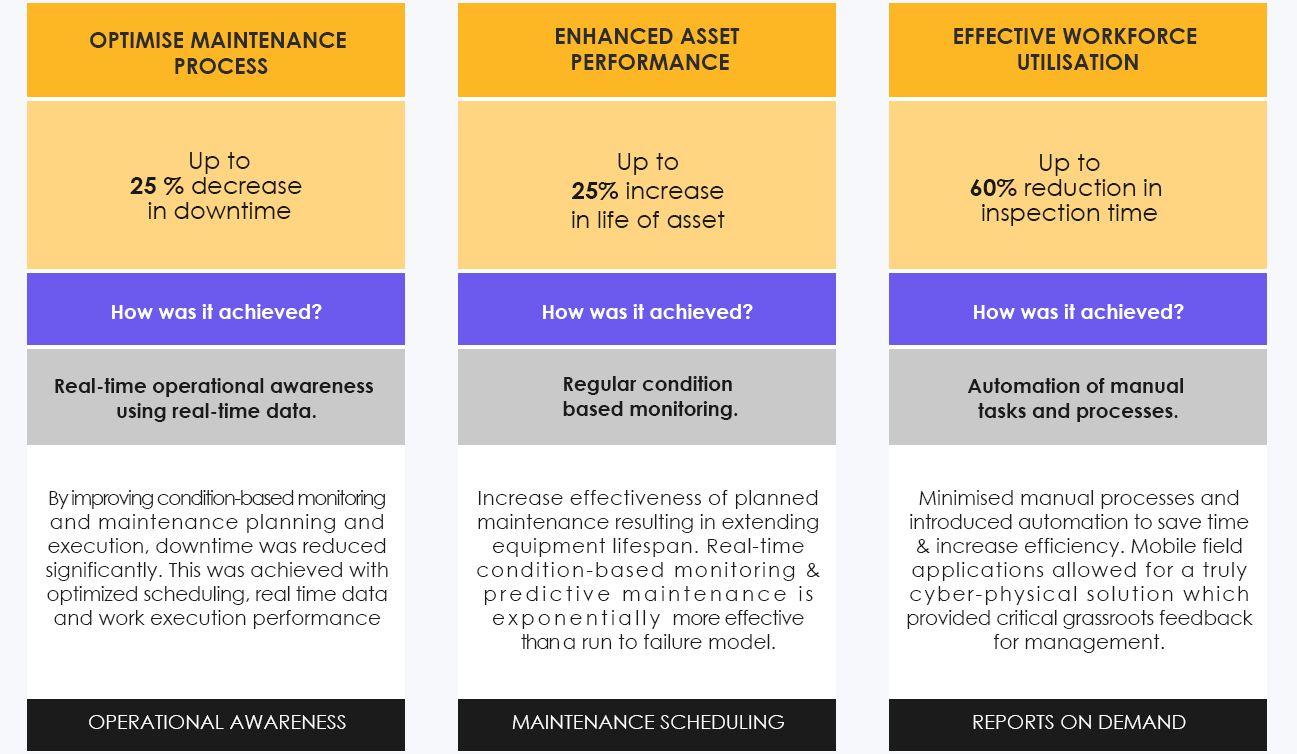

BUSINESS VALUE

Like what you see?

We have some great templates similar to this solution available for you to kick-start your journey.

Still undecided?

Check out our FAQ and Evaluation Guide for more info.

Alternatively, you can contact us at info@devum.com or contact one of our friendly consultants to assist you further.